By Paul Unmack, PE-CSE, ME #116483, www.arprv.com

In my 2016 series of articles, I discussed how RV refrigerators work and how to improve their reliability, efficiency and safety, by controlling the cooling unit boiler temperature with the patented ARP Control. This article will cover cooling unit replacement.

Why Cooling Units Fail

The cooling unit on your refrigerator is dependable as long as the boiler temperature is limited to a level where the water within it is not allowed to boil. The ARP Control (see ad on page 69) will keep this from happening; however, this device has only been available for a short period of time when compared to the age of most RV refrigerators. Therefore, damage to the cooling unit may have occurred before installation of the ARP. The ARP will prevent further damage, but the cumulative damage cannot be reversed.

When failure occurs, the replacement of the cooling unit often is most economical, especially if you are handy and can perform the task yourself. Even if you decide to hire a technician, it’s best to understand the procedure.

Has My Cooling Unit Failed?

Failure of the cooling unit will result in the boiler overheating. If your refrigerator has an ARP Control, it will turn off your refrigerator. Without the ARP, the cooling unit heats rather than cools your refrigerator.

Possible indications that the cooling unit has failed:

• The heat source is on and the refrigerator is not cooling.

Please see article Nov/Dec 2015, “Test Refrigerator Using Both Heat Modes.”

• Unit emits a strong ammonia smell.

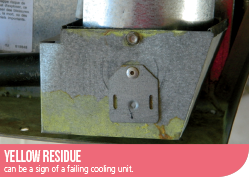

If either of the above is true, turn off the refrigerator and perform a visual inspection. The ammonia smell, or yellow residue, seen in the photo on the next page is a telltale sign that the cooling unit has failed.

• Cooling unit boiler temperature is higher than normal.

The only way to know if the boiler is overheating is to have the ARP Control or use another type of temperature sensor connected to the proper place on the boiler tube.

• Cooling unit heat source is on, but absorber coil is cool to the touch.

This indicates that the ammonia is not circulating in the system. Please see article Oct/Sep 2015, “Cooling Cycle and the Absorber Coil.”

• A gurgling sound, when the heat source is on, indicates that there is a hole in the cooling unit. Gurgling is due to the water in the system boiling, because of low pressure in the system, reducing the temperature at which the water will boil.

CAUTION: If you are unsure how to determine if the cooling unit has failed, I strongly advise turning off your refrigerator and consulting a qualified RV technician.

Cooling Unit Replacement

Steps Once you determine the cooling unit has failed, and you’ve decided to replace the cooling unit, the following steps need to be taken:

1. Use the make and model of your refrigerator to find a manufacturer of that cooling unit. This information is usually on a tag in the door cell of the refrigerator. Here are some questions to ask when ordering, so that you have everything needed to get the job done:

• Does the cooling unit come with the necessary thermal-mastic?

• Is there a core charge, or do you need to return the cooling unit to get a deposit back?

• Are there any special requirements for installation of the cooling unit for your make and model of refrigerator?

2. Other than typical handtools, you may need:

• Caulking gun for the thermal-mastic

• High-quality aluminum HVAC tape (available at hardware stores)

• If the cooling unit does not come with low-expansion spray-foam insulation and it is required for the job, you will need to buy insulation foam.

3. Once the cooling unit is ordered and you have the needed supplies, remove the refrigerator. I recommend making a table, or using blocks and some plywood, on which to slide it. This makes the job much easier.

• With refrigerator removed, next remove the cooling unit controls.

• Remove the old cooling unit.

• Install the new cooling unit.

• Test and reinstall the refrigerator.

Refrigerator Removal 1.

Remove mounting screws.

• On the front side of the refrigerator, the mounting screws can be seen by removing the decorative molding that hide the screw heads.

• The rear of the refrigerator can be accessed through the vent door on the side of the RV. There could be screws holding the unit in, at this location, and they can be seen at the bottom of the refrigerator. On Dometic refrigerators, there are frame rails that sometimes have screws holding it to the RV. On Norcold units, there is a sheet-metal pan, and often screws pass through this pan into the RV.

2. Disconnect electricity, gas and plumbing to refrigerator:

• Shut off/disconnect 120VAC (shore power) and disconnect 12VDC at the battery bank, or remove the 12V fuse that supplies 12VDC to the refrigerator. Disconnect both power lines to the refrigerator.

• If the unit has an ice maker, turn off the water and disconnect the water line. Remove the 120VAC to ice maker.

• Turn off LP gas at tank. Use a stove-top burner to burn off residual LP gas. Disconnect the gas line at the back of the refrigerator and plug the pipe so dirt cannot get in.

Tip: Use your digital camera to take photos of wire position, and identify all wires and/or plumbing with masking tape labels. This makes reinstallation much easier by avoiding guess work.

Remove Fridge from Cabinetry

Once all connections and mounting screws have been removed, one person giving a hard shove from the back of the refrigerator while another pulls from the inside, will start moving it out of its cabinetry. Move the refrigerator into the RV slowly, while checking to make sure nothing is still attached to the unit.

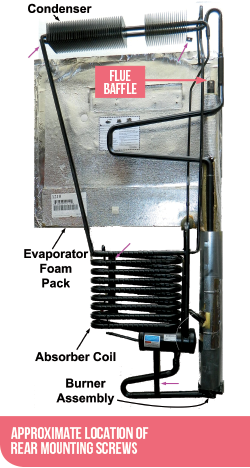

Removing the Cooling Unit

With the refrigerator still upright, the screws that hold the cooling unit into the refrigerated cabinet need to be removed. The blue ovals (in the photo above) show which screws hold the cooling unit evaporator to the freezer and refrigerated portions of the refrigerator. As these screws are removed, use a piece of cardboard and shove the screws into the cardboard to maintain the location that it came from in the refrigerator. Some refrigerators have different length screws in different locations; each screw needs to go back into the same location of the cooling unit if the threads and/or length of the screws differ.

Place padding on the floor of the RV and carefully place the refrigerator face-down. Remove the control board, which will have the following items plugged into it:

• Refrigerator temperature sensor (thermistor)

• Electric heating elements

• LP gas valve

• LP burner igniter

• Some controls have other accessories, such as fans. If you can get a service-manual wiring diagram, it will be helpful. Otherwise, take a lot of photos and mark all connections carefully.

Remove the burner assembly and transfer it to the new cooling unit. The burner assembly will be attached with screws. It is important that the screws be inserted back into the new cooling unit the same way they came out of the old one. On some Dometic cooling units, if a screw is put into the wrong hole, it can cause damage by puncturing the tubing. Also, be careful with the igniter electrode. The porcelain insulation cracks easily, and once it’s cracked, the igniter may not function properly. Be sure to adjust the igniter electrode upon reinstallation of the burner assembly. (www.ARPrv.com/dometic-refrigerator-flame.php.)

IMPORTANT: At the top of the flue tube on the old cooling unit, there is a sheet-metal wind baffle. Remove it to access the flue baffle. The flue baffle is a spiral diffuser on a wire that drops into the flue tube. If this flue baffle is not installed onto the new cooling unit, it won’t work properly on LP gas. Transfer the flue baffle and wind baffle to the new cooling unit.

The boiler housing and electric heaters need to be transferred to the new cooling unit if these parts are not included with the replacement cooling unit. This is the best time to install the ARP boiler temperature sensor according to instructions.

Removing the Cooling Unit

The cooling unit will have screws securing it to the back side of the refrigerator. The purple arrows on the image on the next page, show the approximate locations of the rear mounting screws for this particular cooling unit. These screws can loosen and fall out of the evaporator, so we recommend using Blue Loctite Threadlocker when reinstalling these screws.

Once the rear mounting screws are removed, remove the tape that is around the evaporator foam pack. Usually the cooling unit can be jiggled and lifted to remove at this point. Sometimes the cooling unit can become stuck inside the evaporator foam pack pocket (see the Evaporator Foam Pack Pocket image on page 68). The manufacturers of cooling units recommend using a section of 2×4 as a lever by placing it into the absorber coils and lifting. Check with the manufacturer of your cooling unit to see how they recommend prying the cooling unit out of the evaporator foam pack pocket if it is stuck. Each cooling unit is slightly different, so the installer needs to exercise discretion when prying on it to avoid causing it to rupture.

Preparation for Installation

Up until now, not much skill was needed other than basic mechanical knowledge. Now we share the true secrets that separate the good cooling unit install from the bad one.

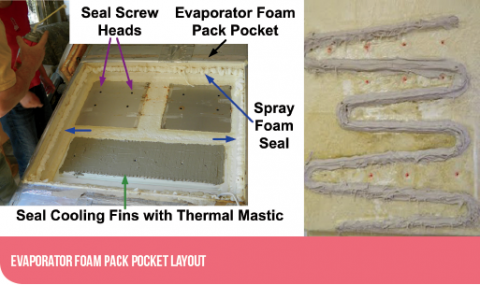

First and foremost, great care needs to be taken to seal the evaporator foam pack into its pocket. Second, do not follow an instruction given by some manufacturers! This instruction includes using thermal mastic around the sealing joint between the evaporator foam pack and the pocket. Why would one want to put a thermal conductor where an insulator should be? Therefore, if you have a cooling unit that has Thermo-Mastic in the sealing joint, take time to scrape it all out. Also, remove all the Thermo-Mastic on the back side of the cooling fins. This part of the process is highly important. We cannot emphasize enough how important it is to apply the Thermo-Mastic properly, in addition to sealing the evaporator pocket so that condensation does not ruin your handiwork.

Saturation of Insulation and Sealing Tape

After the cooling unit has been removed, care needs to be taken to remove all the old tape and clean the surface where the new tape will adhere around the evaporator pocket joint. Be sure to use high-quality aluminum HVAC tape, not the cloth duct tape that some manufacturers use. Also, at this point it is imperative to inspect the insulation around the evaporator pocket for moisture. If the evaporator pocket was not sealed properly, let’s say the tape was deteriorated, allowing moisture to condense on the evaporator, the water will saturate the refrigerator cabinet insulation. Carefully check the bottom of the evaporator pocket insulation for signs of water saturation. Look for stains where water ran down the back side of the refrigerator from the evaporator. Also, push on the insulation to see if water comes out or if the insulation feels damp. If there is water in the insulation, allow it to dry for a few days before installing the new cooling unit. This is the reason we recommend removing the refrigerator as soon as possible and letting it sit without the cooling unit in the cabinet. Heat from a light bulb inside the refrigerator cabinet space can help speed up the drying process.

Cooling Unit Installation Dry Run

Once the refrigerated cabinet has been cleaned, we recommend a dry run installation of the cooling unit into the refrigerator.

Lay the cooling unit down into the cabinet to make sure that the evaporator foam pack fits into the pocket properly. The foam pack should seat all the way into the pocket. If it doesn’t, trim any foam from the evaporator foam pack that may be interfering with a proper fit. Another advantage to this dry run is that you and your helper have a chance to coordinate setting the cooling unit into the cabinet for optimum alignment.

The evaporator should be set into its pocket evenly. Things get messy and sticky in the next step, so let the dry run be where any potential problems get worked out. The refrigerator needs to be set upright quickly in the next step to insert the screws into the evaporator from the refrigerator side. The dry run sees to it that the next phase goes as fast as possible.

Seal Evaporator on Fridge Side

When all the old thermal mastic has been cleaned out, the insulation in the refrigerator cabinet is dry and the surface around the evaporator pocket has been cleaned with something like 409 (my favorite), it is time to apply the Thermo-Mastic. The refrigerator shown in these photos is a Norcold, and the cooling fins in the refrigerated compartment are made accordion-style. This method of manufacture allows moisture to enter through the slits in the cooling fins. We at ARP have found a way to seal the cooling fins and increase efficiency. As seen in photo above, the cooling fins have been sealed with a thin layer of Thermo-Mastic, using a putty knife. No matter if you have a Dometic or Norcold refrigerator, the objective is to keep air out of the evaporator. Air can get to the evaporator either from the back side through the gap between the foam pack and the fridge, or from within the fridge itself. Air infiltration brings water vapor; water vapor condenses on the evaporator coils and then drips down, destroying the insulation and rotting the evaporator tubing.

Application of Tape and Thermo-Mastic to Evaporator

The new cooling unit needs to be prepared for installation by application of the sealing tape and Thermo-Mastic. On Dometic cooling units where the cooling unit has a frame member blocking the installation of the evaporator sealing tape, it is a good idea to put the tape on before installation. Run tape around the outer periphery of the evaporator foam pack, so that the tape is half way on the evaporator foam pack and halfway off the foam pack so that, when the foam pack in inserted into the refrigerator, the half of the tape will stick to the refrigerator cabinet. Here’s the trick: Remove the backing for the tape to stick it to the foam pack, and then put the backing back on the half of the tape that is going to attach to the refrigerator cabinet. This prevents the tape from sticking to anything before it should. Once the evaporator has been put into place, pull the tape backing off to make a perfect seal.

Seal Evaporator—Insert Cooling Unit

Now that the evaporator foam pack has tape, and the tubes have a thick layer of Thermo-Mastic on them, the final step before inserting the cooling unit into the refrigerated cabinet is to use low-expansion spray foam to seal the outside joint of the evaporator pocket. Before applying the spray foam, make sure you are ready to insert the cooling unit into the refrigerator.

Spray the foam around the outside edges of the pocket. Referencing photo above: Note the blue arrows point to a bead of spray foam about one-inch thick around the circumference of the evaporator pocket on the sealing surface. Once the spray foam is in place, set the cooling unit carefully, and evenly, into the refrigerated cabinet. Insert at least two of the cooling unit rear-mounting screws, and then, placing the evaporator foam pack inside it, press as hard as you can, while the refrigerator is still on its face.

Immediately, lift the refrigerator to the upright position and start inserting the screws from the inside of the refrigerator, into the evaporator.

Tip: Silicone sealant can be used to seal under the head of the screw to prevent water from wicking into the evaporator. Start with the center screws and work your way out to the outer screws with a spiral pattern of insertion and barely tightening them. The idea is to fasten down the evaporator from the center before the edges. Tighten the screws in about three passes. The first pass snugs up the screws, the second pass tightens a little tighter and squeezes the Thermo-Mastic. The third pass fully tightens each screw.

Lay Refrigerator Back Down and Finish Installation

Now that the evaporator screws are inserted from inside the refrigerator, lay the refrigerator back down and finish taping the evaporator joint and reinstalling all of the accessories onto the cooling unit. Three areas of care need to be taken; the first is that the flue baffle needs to be put back in. The second is getting the LP gas igniter adjusted properly. Finally, before putting the refrigerator back into its cabinet, let’s get the the fluids where they belong in the cooling unit tubing. This step is important because the weak solution cavity in the boiler assemble can get drained with all the twisting and turning of the cooling unit during transit and installation. Simply roll the refrigerator onto the boiler side. This allows the fluid in the cooling unit holding tank to run down into the boiler. When the refrigerator is tipped upright again, the fluids will run into the weak solution cavity. Repeat laying down the refrigerator so that the cooling unit boiler is closest to the ground and the holding tank is above; repeat this step a number of times to send the fluids where they belong in the cooling unit.

Now you are ready to reinstall the refrigerator and run it. If you have installed an ARP Control, we recommend running the new cooling unit for about a week before turning it on. This allows time for the fluids to fully mix in the cooling unit. The ARP is highly sensitive and will turn off the cooling unit unnecessarily during this break-in period if not turned off.

Fridge for Life—Conclusion

With a properly installed cooling unit, and an ARP Control protecting it from the beginning of the refrigerator’s life, your cooling unit should last as long as your RV. As long as the boiler of your refrigerator is not overheated, and no mechanical or electrical parts fail inside the cooling unit, we can say with confidence your refrigerator could last as long as your RV, given that there are not any cooling unit manufacturing defects.

Our first refrigerator outlasted three RVs and had about 300,000 miles on it when I killed it by operating it off-level. We also have a Servel refrigerator that has run faithfully for 81 years without any cooling unit replacement.

Paul and Mao Unmack are mechanical engineers. Paul ran an automotive repair business in Red Lodge, Montana, for 20 years before receiving his engineering degree. He has practiced nuclear, fire suppression and industrial process control systems design. Mao designed pressure vessels for ammonia plants in China for 12 years, then came to the U.S. to get a master’s of welding engineering. She designed biodiesel plants and worked for a government-funded research and development organization. Paul and Mao run the entire ARP control business while taking on engineering consulting gigs.